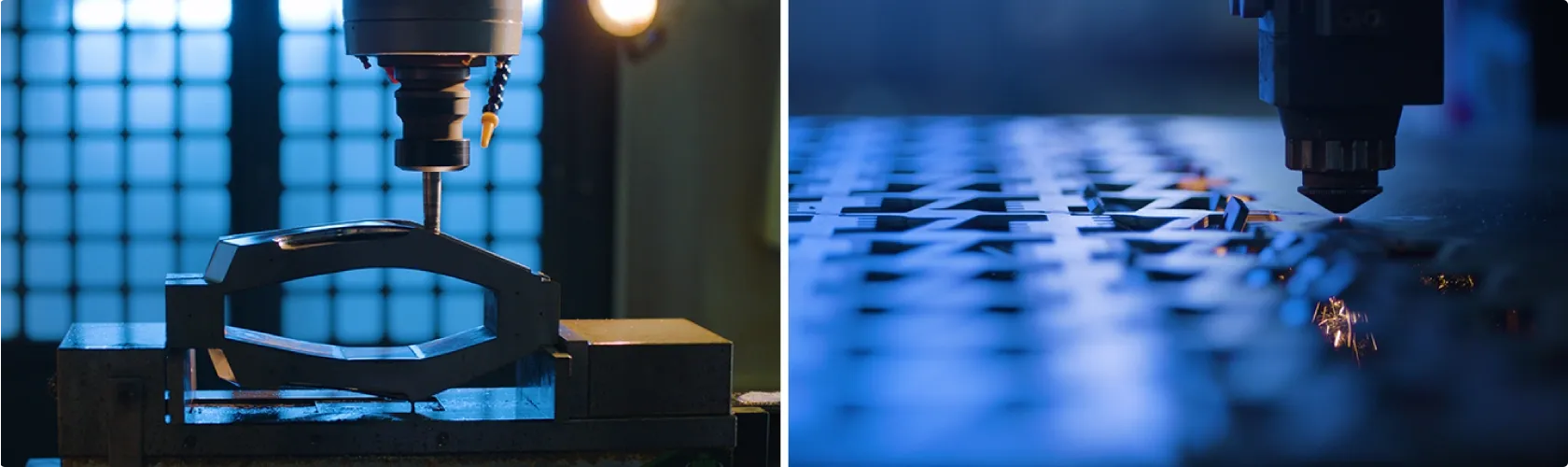

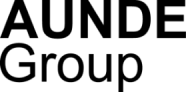

OUR DEVELOPMENT & MANUFACTURING COMPETENCE

ISRI HUATAI fully implements the IMS (integrated management system)of ISRI Group, which integrates eight international management systems, and establishes an information management system from product development to factory operation, providing scientific management support for the company's operation and sustainable development, so as to continue to exceed the growing expectations of customers.